With the ongoing development of new technologies and systems, the automotive sector is always evolving. In order to be able to maintain and fix the newest automobiles on the road, auto repair businesses must stay current with these developments. Customers’ expectations and requests vary as new technology and functionalities become available. Workshops that keep up with industry advances are better able to serve their customers’ demands, prevent stagnation, and do not run into the danger of losing clients. The workshops can run more effectively thanks to new technologies, tools, and procedures, avoiding errors and downtime, which can boost production and profitability. The Society of Indian Automobile Manufacturers (SIAM), the Automotive Research Association of India (ARAI), and other organisations govern the Indian automotive industry. For car workshops to retain compliance and avoid penalties, it is imperative to stay up to date with the standards and laws that are changing.

Changes in Automobile Technology

Fossil fuel-powered cars predominated on Indian roads for a very long time. However, with the times changing and a greater emphasis on sustainability, electric vehicles have begun to gain ground and within the next few years, sales may increase significantly Modern electric vehicles differ from traditional fossil fuel-based vehicles on three levels: the hardware, the software, and the interfaces. In hardware, we see an increase in the number of electronic and electrical components. The mechanical systems have also got significantly modified to match the new power type. The powertrain, energy storage, driving dynamics, and other aspects of the vehicle’s construction and functioning have been altered.

The maintenance requirements for electric vehicles have also transformed as a result. Let us discuss a few of these aspects:

Electric motor: An electric motor replaces the internal combustion engine in electric cars. An electric machine that transforms electrical energy into mechanical energy is a motor.

Transmission: Since electric motors can generate their maximum torque at 0 revolutions per minute (RPM), unlike internal combustion engines, which need numerous gears to work at their best, electric cars typically have a single-speed transmission.

Cooling system: Internal combustion engines produce more heat than electric motors, which reduces the need for cooling. EVs could have no cooling system at all or one that is smaller and simpler.

Fuel system: Since the energy is stored in the battery pack, electric vehicles don’t need a fuel system, whereas internal combustion engines do because they need a fuel tank, fuel lines, and a fuel injection system.

Exhaust system: In contrast to internal combustion engines, which burn fossil fuels, electric vehicles have no exhaust emissions. These pollutants can be hazardous to the environment and human health. Consequently, EVs do not need an exhaust system.

Suspension and brakes: Electric vehicles may require different suspension and braking systems to accommodate the extra weight of the battery pack and the lack of a traditional powertrain.

Battery pack: EVs’ battery packs, which are often made up of hundreds of individual lithium-ion cells, are used to store electrical energy. Because the battery pack weighs more than a petrol tank, it might change the weight distribution and necessitate changing how the suspension is tuned.

From Hardware-Defined to Software-Defined

IC engine vehicles were mostly hardware defined which means that OEMs could work on the hardware itself to create distinct differentiation. But the new age vehicles are becoming more software-defined which means software embedded in the vehicle system will define its performance. With this change, the majority of the systems in the vehicle might see getting over-the-cloud updates for better performance while the hardware does not change at all for years. This might make maintenance easy but has the potential to reduce the dependence on independent car workshops for vehicle maintenance since most of these software updates would happen from the OEM themselves.

With the cars becoming more software-defined the distinct changes might be as below:

Onboard computers: Vehicles are being equipped with more powerful onboard computers to handle the increased data processing and connectivity requirements. These computers can handle tasks such as navigation, infotainment, and advanced driver assistance systems (ADAS).

Networking hardware: Vehicles are being outfitted with networking hardware such as cellular modems and Wi-Fi routers to enable connectivity to cellular networks and local networks. This allows vehicles to connect to the internet, access cloud services, and communicate with other vehicles and infrastructure.

Sensors: Vehicles are equipped with a wide range of sensors, including cameras, lidar, radar, and ultrasonic sensors, to enable features such as ADAS, parking assistance, and autonomous parking.

GPS: Vehicles are being equipped with GPS and GNSS receivers to enable location-based services such as navigation, mapping, and real-time traffic updates.

Short-range communication: Vehicles are being equipped

with short-range communication technologies such as Bluetooth and NFC to enable features

such as keyless entry, phone pairing, and wireless

charging.

OBD-II Connectors: With the increase of connected cars, vehicles are now equipped with OBD-II connectors that allow aftermarket devices to be plugged in and access the vehicle’s data.

Apart from this, there is a lot of preloaded software in modern-day cars that analyse the data coming from the various sensors and other electronic components and manage critical systems like battery management, vehicle energy management, active safety systems, etc.

Changes in Workflow and Operations

The current state

A typical car workshop in India responsible for providing maintenance support for internal combustion engine (IC) based cars operates by following a set process. The workflow typically includes the Inspection process which is the first, where the mechanics check for any visible signs of wear and tear, fluid levels, and other issues. Then the mechanics will use diagnostic tools to identify the specific problem if any issues are identified during the inspection process. Once the problem is identified, the mechanics will repair or replace any necessary parts. The mechanics then will also perform regular maintenance tasks such as oil changes, tire rotations, and brake inspections. After the repairs and maintenance are completed, the mechanics will take the vehicle for a test drive to ensure that everything is working properly. Finally, the car will be cleaned before it is handed back to the owner.

Overall, the process is focused on identifying problems, performing repairs and maintenance, and ensuring that the vehicle is safe and running smoothly before it leaves the workshop. Today in India, most of the activities performed in a typical workshop are manual and the effectiveness of the work depends on the experience and expertise of the mechanics involved. Car workshops servicing IC engine vehicles have a typical look which is interesting to note. They might have several bays for lifting and working on cars, as well as designated areas for storing tools and equipment. The workshops often have a strong smell of oil and gasoline, and the floors are usually covered in grease and grime. The mechanics working in these workshops can often be seen covered in dirt and grime from working on engines and powertrains. Manual labour is a significant aspect of the work, as mechanics use a variety of hand tools to disassemble and reassemble engines, transmissions, and other components. The work can be physically demanding and requires a high level of skill. Overall, it is a dirty and greasy environment with a lot of manual labour.

The change

In the future, car workshops for electric vehicles will look far different than the car workshops of today. With the increasing number of connected electric vehicles coming into workshops for maintenance, much of the work that was once done manually can now be done with less manual intervention and more automation. Sensor technologies and embedded components are increasingly becoming the norm for electric vehicles, allowing for maintenance updates to be performed over the cloud and for problems to be identified more quickly and accurately. With the increase in automated processes, car workshops will become more efficient, with less time spent on manual labour and more time devoted to higher-level processes and problem-solving. Moreover, the need for technicians who are knowledgeable in the complexities of electric vehicles will become more pronounced, as the complexity of the vehicles continues to increase. In sum, car workshops of the future will look quite different than the car workshops of today, due to the increased prevalence of electric vehicles and the advancements in technology that come along with them.

Challenges and benefits

Automobile workshops providing maintenance support to internal combustion engine (ICE) vehicles will face both benefits and challenges in the transition to providing maintenance for electric vehicles (EVs). One potential benefit is that the transition can result in increased efficiency, as technicians can spend less time on manual labour and more time on higher-level processes and problem-solving. The increased complexity of EVs can also present an opportunity for workshops to expand their services and offer more specialised maintenance support. On the other hand, the transition from ICE to EVs presents some challenges as well. Workshops may need to invest in new equipment and personnel training in order to be able to provide the same level of service to EVs as they currently do to ICE vehicles. Additionally, they may face increased competition from other workshops that may specialise in EV maintenance. In order to be successful in providing maintenance services for electric vehicles, automobile workshops will need to be able to keep up with the latest advances in technology. This will require training of personnel to understand the complexities of EVs, as well as investing in the necessary equipment. Additionally, workshops will need to have access to the necessary parts and components, as well as the expertise to be able to diagnose and repair any issues that may arise. Furthermore, it is important for workshops to develop a good relationship with EV manufacturers, as this will allow them to stay up to date on any new developments and have access to any parts or components that may be needed. Finally, it is essential that workshops create a customer-friendly environment, as this will ensure that customers feel comfortable entrusting their vehicles to the workshop. By taking these steps, automobile workshops can ensure that they are able to successfully provide maintenance services for electric vehicles.

Challenges due to these changes

To prevent customers from using privately operated vehicle workshops for any type of maintenance work, many OEMs are attempting to train their own personnel and service centre executives. The fundamental technological expertise needed to handle electric vehicle maintenance is a major factor in this. An automobile is becoming less of a combination of multiple individual items and more of a system as there are more and more electronic parts and embedded software in the system. OEMs worry that if a component is not properly maintained, it could affect the entire vehicle and cause customers to dislike the brand. An error in one component’s maintenance could have an effect on the entire vehicle. Due to cars being maintained at individual workshops rather than authorised service centres, there were several calibration problems when multipoint fuel injection first became common in automobiles. Several OEMs have already begun planning to offer extended warranties of up to 8 years to the most crucial components of the automobile, such as the electric drivetrain, battery systems, ECU, embedded software, etc. This might be a cause of worry for car workshops.

New business opportunities

It is essential to provide electric charging infrastructure for customers’ convenience given the rise in electric automobiles. A vital component without which an electric car is essentially worthless is charging. Imagine a five-story building with a single infrastructure to support all the parked electric vehicles. Customers may experience significant inconvenience as a result, which presents an excellent commercial opportunity for auto repair firms. Workshop owners may wish to collaborate with OEMs or establish a line of business where the major value proposition, in addition to offering regular maintenance assistance, is assisting the clients in putting up their own charging infrastructure. With increasing electric vehicle sales on the market, a new, interesting business option becomes available. There will come a day when customers will look to dispose of their end-of-life cars, and both the customer and the OEMs will be concerned about the safe disposal of critical components. Providing value in safe electric car dismantling and disposal presents car workshop operators with yet another enormous chance to cash on.

Training and Up-skilling

Importance of training

As the number of electric vehicles on the road increases, car workshops must invest in training and upscaling their workforce in order to keep up with the changing technological landscape. Automated processes are becoming increasingly prevalent, allowing for maintenance updates to be performed over the cloud and for problems to be identified more quickly and accurately. With the increase in automated processes, car workshops will become more efficient, with less time spent on manual labour and more time devoted to higher-level processes and problem-solving. To keep up with these advances, car workshops must ensure their technicians have the knowledge and skillset to effectively service electric vehicles. Additionally, upscaling the workforce to include more technicians with specialised knowledge of the complexities

of electric vehicles will be essential for car workshops to continue providing excellent service in the future.

What to be trained on

To operate a workshop where maintenance of electric vehicles happens, one should make sure that the mechanics working on the high-voltage components of the car are certified by TUV SUD to handle those components. There are certain norms that one needs to comply with in India to assemble and disassemble electric vehicles. Employers are responsible for ensuring employee safety and are required to follow the Indian Standard for Occupational Safety and Health established

by BIS.

Mechanics in car workshops who were used to working on vehicles with internal combustion engines (ICEs) will need to upgrade their skills to provide maintenance assistance for electric vehicles (EVs). With EVs, mechanics must understand the different powertrain components, such as the electric motor, battery, and associated electronics. They must also be familiar with the various sensors that operate the vehicle, such as the brake pedal, steering wheel, and accelerator. Understanding how these sensors work is essential for proper maintenance and repair. In addition to the mechanical components, mechanics must also be familiar with the in-car software. This software assists with the various functions of the vehicle, such as controlling the engine, monitoring the powertrain, and providing diagnostic information. Knowing how to use and troubleshoot this software is essential for providing EV maintenance and repair services. Understanding how EVs operate is essential for any mechanic servicing them. Many EV components are similar to those found in ICE vehicles, but some have unique features, such as regenerative braking, which is not found in ICE vehicles. EVs also have different power sources and require different types of maintenance. For example, rather than changing an oil filter, an EV’s battery may need to be inspected. Finally, mechanics will need to be familiar with the safety requirements of EVs. These vehicles have high-voltage electrical systems and require special safety protocols for emergency response and maintenance. Mechanics must be aware of the potential hazards and understand the best practices for responding to an EV emergency.

Getting Trained

This is the right opportunity for someone to advance their skills and join the elite group of auto workshop technicians who have a thorough understanding of electric vehicles and can offer top-notch maintenance assistance. The learners might be categorised into three levels:

Beginners – people who are unfamiliar with electric vehicles, have never worked on one, or have primarily handled automobiles with IC engine vehicles. Beginners might not immediately work on a vehicle but will like to equip themselves with the knowledge of handling one.

Practitioners – those who might have a theoretical understanding of electric vehicles and are looking to enhance their skills by working in this domain. The practitioners might want to work as electric vehicle mechanics soon.

Experts – those who have more than a year of experience working on electric vehicles and are looking to become senior supervisors.

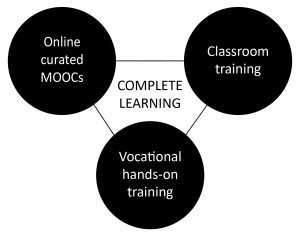

To upskill the workforce for all three of these levels, a systematic blended approach should be adopted:

Online curated MOOCs – There are many online available free courses offered by different platforms which are suitable for introduction to certain concepts. Reach out to receive a carefully curated list of courses (chosen courses for individual topics based on how good they are). This ought to act as foundational knowledge and should raise awareness of the subject.

Classroom training – One should attend classroom sessions after taking the curated online courses to connect physically with the instructor and have a deeper understanding of the new concepts.

Vocational hands-on training – After completing the classroom training a learner should get practical exposure to hone their skills further. There are certain organisations that provide such extensive practical interventions.

Vocational hands-on training – After completing the classroom training a learner should get practical exposure to hone their skills further. There are certain organisations that provide such extensive practical interventions.

For a novice to feel comfortable working on an electric vehicle, it is crucial to have the experience of witnessing how one is disassembled and reassembled. This is why it is so important to combine theoretical knowledge with actual experience. However, for a practitioner and expert getting trained to work on an electric vehicle having training done on High Voltage systems is mandatory.

One might get in touch with the author for more information on how to implement the methodical strategy described in this section for upskilling yourself or your workforce.

Acknowledgment

This piece combines my personal experience working in the industry with conversations I have had with some automobile industry specialists. I want to express my gratitude in particular to Dr Shankar Venugopal, Vice President of Mahindra & Mahindra Ltd., for giving his perspectives on how he sees the changes taking place in the sector and how they can affect automobile workshops in the future. I also want to express my gratitude to Dr Ranga Srinivas Gunti, General Manager, Head Talent Development at Tata Motors (TPEML), for giving his thoughts on how OEMs are getting ready to address the maintenance issues with electric vehicles.

Conclusion

In conclusion, the rise of electric vehicles is bringing about significant changes in the automobile industry, including in the design of car bodies and the procedures used in car workshops. These changes present both challenges and opportunities for car workshop owners and their workforce. To stay competitive, it is important for workshop owners to stay informed about the latest developments in electric vehicle technology and to invest in training their workforce to be able to provide maintenance support for these vehicles. With the right approach, car workshops can navigate these changes and continue to thrive in the new era of electric mobility.

Author

Academic Director

National Institute of Innovation and Entrepreneurship Management (NIIEM)