In the dynamic world of automotive engineering, the pursuit of a seamless and comfortable driving experience is paramount. Noise, Vibration, and Harshness (NVH) issues, including rattles and chatter, can significantly impact the overall driving comfort and vehicle performance. Often overlooked but crucial in addressing these challenges is the use of specialty grease for in-car components. This article delves into the pivotal role that specialty grease plays in mitigating NVH problems, ensuring a refined driving experience for consumers.

NVH?

NVH is a collective term that encapsulates undesirable noises, vibrations, and harshness experienced by vehicle occupants. Rattles and chatter are common issues arising from the continuous movement and interaction of various components within the vehicle. These problems often stem from insufficient lubrication, leading to friction and wear between moving parts.

Specialty Greases – Geed and Importance

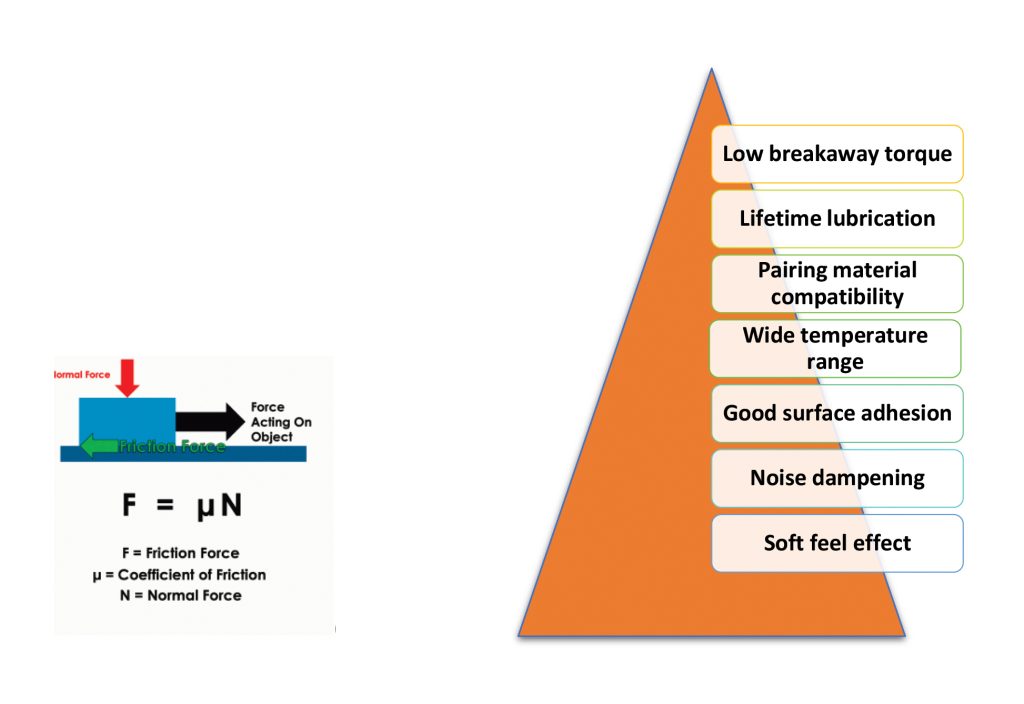

Specialty greases are formulated to meet the unique demands of automotive applications. When applied to in-car components, these greases act as a protective barrier, reducing friction, minimising wear, and dampening vibrations. Their unique composition includes additives that enhance their ability to withstand extreme conditions, such as temperature variations, vibrations, and low-speed movements.

Reduction of Friction in Material Pairings

Specialty grease’s primary function is to reduce friction between moving parts. In automotive components like vehicle access systems that include control cables, locks and latches, door hinges, window regulators, comfort and seating components, suspension joints, and steering systems, friction can result in irritating rattles and vibrations. Specialty greases, formulated with select raw materials with relevant chemistry, and enriched with advanced additives, create a lubricating film that prevents metal-to-metal contact. This ensures smooth operation and minimises the potential for NVH issues.

Noise and Vibration Control

The damping properties of specialty greases play a crucial role in addressing rattles and chatter. As components move and interact, vibrations are generated. Specialty greases absorb and dissipate these vibrations, effectively reducing the transmission of noise throughout the vehicle. This noise-damping capability is particularly beneficial in critical areas such as the in-car components in the User Interactive Zone (cabin area), where such unwanted vibrations can resonate and amplify, leading to unwanted and unpleasant sounds.

Long-term Performance

Automotive components endure a wide range of environmental conditions and operational stresses. Specialty greases are engineered to provide long-lasting lubrication, maintaining their effectiveness over extended periods. This durability ensures sustained friction reduction and noise damping, contributing to the overall longevity and reliability of the vehicle and comfort for the user over the vehicle’s lifetime.

In Conclusion:

In the pursuit of a quieter and more enjoyable driving experience, the role of specialty grease in addressing NVH issues is indispensable. By reducing friction, damping vibrations, and ensuring long-term performance, these greases significantly contribute to the refinement of in-car components. Automotive engineers and manufacturers must recognise the importance of selecting and applying the right specialty grease to optimise the performance of various components, enhancing the overall driving experience for Automobile enthusiasts. As the automotive industry evolves, the use of advanced specialty greases will remain a key strategy in achieving quieter, smoother, and more comfortable rides.

Paramjeet Singh Karir

Head – OEM & Strategic Business

Molygraph Specialty Lubricants, Mumbai, India

www.molygraph.com