Manufacturers of auto refinish/repair coating systems are looking to enhance the efficiency of the entire repair process in order to optimise body shop throughput. Apart from fast curing the refinish coatings are expected to match the original appearance and surface finish with exceptional performance properties similar to OEM coatings.

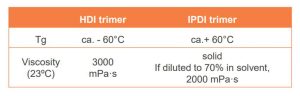

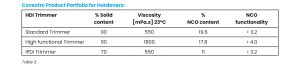

Covestro provides a wide range of high functional HDI Trimmers and IPDI Trimmers as the hardener component for lightfast, rapid-drying polyurethane coatings to match factory-applied coatings.

Introduction:

Key reasons for the success of aliphatic polyurethanes in auto refinish are their robustness, quality, efficiency and ecological.

Robustness: Low bake (up to 60°C) and room temperature drying possible with shorter drying cycles (30 min), this leads to low dust uptake and smooth finish.

Ecological: Lower solvent content needed than that of competing nitrocellulose and alkyd finishes. High solid coatings possible hence reduced VOC.

Quality: OEM coatings like high gloss even without polishing can be achieved with superior solvent, chemical and scratch resistance. Apart from this high hardness, flexibility and outstanding durability are added benefits.

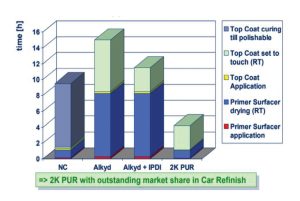

Efficiency: Fast drying and high sandability means car painting is possible in shortest time with fewer spray cycles and high material efficiency. (Fig: 1)

Apart from standard hardeners like biurets and Trimmers Covestro has specialty polyisocyanates such as high functional Trimmers, IPDI Trimmers which proved to be key contributors for fast curing demands of growing auto refinish market.

High Functional HDI Trimmers:

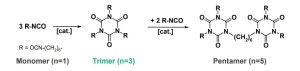

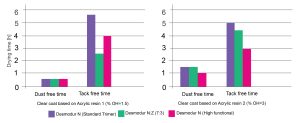

Different oligomer distribution leads to different viscosities and different drying times. As against standard Trimmers high functional Trimmers are faster drying. (Fig: 2)

High functional Trimmers greatly enhance film performance. It provides high crosslinking density, better chemical and solvent resistance than that of standard Trimmer along with high UV resistance.

IPDI Trimmers:

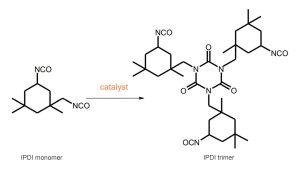

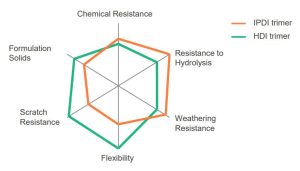

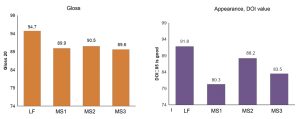

Isocyanurate trimmers based on IPDI available in a number of solvent blends, these polyisocyanates are less reactive than Desmodur N polyisocyanates and produce more rigid films. Isocyanurate Trimmers based on IPDI are marketed by Covestro under the trademark Desmodur Z. Two-component polyurethanes formulated with Desmodur Z as the sole polyisocyanate or in blends with Desmodur N polyisocyanates generally have shorter tack free times than when using Desmodur N types as the sole polyisocyanate. Desmodur Z polyisocyanates are compatible with alkyd paints containing aliphatic hydrocarbon solvent blends. Addition of Desmodur Z polyisocyanates to these paints usually results in faster drying properties, harder films, and improved gloss. (Fig: 3, 4 & 5)

IPDI Trimmers (Desmodur Z) as Reactive Diluent:

Desmodur Z (70% solids) can be used as a drop-in solution to speed up physical drying performance of coatings. It provides numerous benefits such as faster physical drying, improved hardness, solvent resistance, weatherability, enhanced gloss retention, extended pot life due to secondary NCO groups.

Recommendation: IPDI Trimmers can be used in combination with HDI Trimmers to improve physical drying performance of acrylic coatings. It can be used as sole crosslinker with alkyd resin based coatings. Recommended ratios are 70:30 or 80:20 by weight (HDI:IPDI) for acrylic coatings and 10-15% for alkyd coatings. Blend with Desmodur N type of polyisocyanates further improves chemical resistance, UV resistance and overall film hardness (increased Tg)

Properties of Clearcoat Based on Different Polyurethane Hardeners:

The results clearly shows that High functionality Trimmer Desmodur N and combination- Desmodur N:Desmodur Z provides faster reactivity and improved drying characteristics without compromising optical properties like gloss and haze. However films with standard IPDI hardener alone found to be brittle. (Fig: 6)

Comparative drying performance:

The characteristics of resin used to formulate also has an impact on drying and other performance, however high functional Trimmer and N:Z (standard Trimmer+IPDI Trimmer) combination certainly shows improved results than the standard Trimmer.

Effect of Polyol on Srying:

Acrylic resins are important co-reactants in polyurethane finishes for auto refinish. With high molecular weight acrylic resins excellent weathering resistance and very fast physical drying coatings are possible.

Super-fast Drying Clear Coat – Comparative Performance Study in Lab at Low Temperature Conditions:

Market clear coat samples which are used for polyurethane refinishes were studied with Covestro high functional Trimmers 10-20°C temperatures. Super-fast drying clear coat prepared in lab for comparative study was formulated with hyperbranched acrylic resin as co-reactant and high functional HDI Trimmer as hardener component. This clear coat system was found to be better in terms of gloss and appearance compared to other market samples. (Fig: 8)

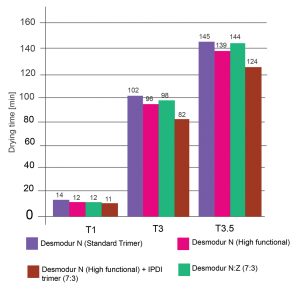

In another study same clearcoat studied with combination of High functional Trimmer+IPDI trimmer (7:3) with other hardeners at 10°C (Fig: 9).

For lab study T3 can be imitated as polish time in auto refinish (For T3 200g and T3.5 500g weight is taken to check drying test in lab). Even at lower temperatures T3 of combination High functional Trimmer and IPDI Trimmer found 20% shorter than standard Trimmer (Figure 9). The combination markedly improve the polishing time without affecting appearance.

Summary:

Auto refinish coatings based on High functional aliphatic trimers and IPDI trimers provides superfast drying plus high-quality performance. Exceptional gloss and appearance is possible to achieve even at lower temperature conditions at faster curing speeds.

Author

Sachin Kamble

Application Development

Covestro (India) Private Limited