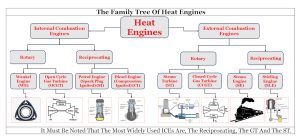

Preamble: The defining characteristic of our present civilisation, setting it apart from all others previous civilisations, is the widespread utilisation of mechanical power. In the past, human muscles served as the primary source of power for various tasks, whether in times of peace or war. Later, animal power was harnessed to aid in labor, along with the harnessing of wind and water power which further expanded the capabilities of humans to get more work out from available resources. However, the most significant leap occurred when humanity mastered the art of converting energy from one form to another, giving rise to the invention of various kinds of engines, starting from the first windmill ofthe 9th century in Persia. Conversion efficiencies have always been a crucial factor for these engines while transforming energy from one form to another. These “engines”, have played a pivotal role in modern society. A windmill, converting wind power into rotational energy is known to be the oldest such engine (also called “wind engine”). These windmills were used throughout the high medieval and early modern periods. Then came the “steam engine, invented by Thomas Newcomen in 1712, which was later improvised by James Watt in 1769, ushering in the age of the industrial revolution. Most of such “engines”, today convert the “heat energy” stored fossil fuel (i.e., coal & petroleum) into workable mechanical energy – thus the name the “heat engines”. Among these “heat engines”, the Internal Combustion Engine (ICE), became a prime mover of second wave industrial revolution (which had begun with the invention of “steam engine”). The “Internal Combustion” in the name refers to the fact that fuel is combusted internally in a closed space to produce the required mechanical power. It may be noted that it is only recently the term “ICEV” (Internal Combustion Engine Vehicle) has gained popularity, particularly with the rise of Electric Vehicles (EVs), which are celebrated as environmentally friendly vehicles due to their lack of localised toxic pollutant emissions. EVs are driven purely by electrical energy (ironically almost 63.3% of global electricity comes from fossil fuels, while renewable energy accounts for 26.3% and nuclear energy for 10.4%) stored in batteries, while ICEVs rely on direct burning of fossil fuel (in ICEs) for propulsion.

The History of ICE: The history of ICEs can be traced back to the latter half of the 19th century, when a variety of such engines were being tried out & constructed by many engineers across the globe. These engines exhibited variable levels of success, depending on their design, type of fuels used, associated mechanical systems, and engine cycles employed. However, it was Nikolaus August Otto, a German engineer, who in 1876 developed an “Otto Cycle” engine known today as the gasoline engine (it uses an external spark to ignite air-fuel mixture which gets compressed to about 120~200 psi). These engines were initially used for stationary installations, as Otto had no interest in transportation. Other engineer such as Daimler perfected the Otto engine for transportation use and which is widely used in cars, scooters, power boards, small gensets, etc. today. By 1892, another German engineer, Rudolph Diesel, came out with another type of engine i.e., Diesel engine (it uses higher compression pressure of about 300~500 psi to self-ignite air-fuel mixture and hence does not need any external spark for ignition. This was based on “Diesel Cycle” which was designed to use Diesel, a heavier fuel and was more powerful than gasoline engines. Diesel engines are more commonly used in heavy machinery, locomotives, ships, and some automobiles esp. long-haul commercial vehicles.

Over the time significant advancements have turned both of these ICEs into technological marvels and many of these ICEs are used in a variety of stationary & mobile applications2 accounting for about 25% of the world’s power needs. However, growing awareness and global concern about environmental degradation have impacted the reputation of ICE engines, particularly in the mobility sector. As a response, there have been proposals to replace ICEVs with alternative fuel vehicles, aiming to reduce vehicle greenhouse gas emissions and mitigate environmental impacts.

The Present: The transport of goods and people is essential to modern society, and currently, the majority of transport is almost entirely powered by ICEs using liquid fuels due to their plentiful supply, convenience, and affordability. Also, the brilliance of oil as a fuel is its transportability, due to its liquid form, versus solid coal and gaseous natural gas. It also contains over 50% more chemical energy than coal, at a “heating value” of 46 MJ of energy versus 26~33 MJ for the highest-quality coals. Because of its liquid form, one supertanker of two million barrels provides the same amount of energy as 30 full coal trains with 100 cars carrying 115 MT of coal each. While natural gas contains even more energy, its gaseous nature made it difficult to transport in most countries, at least until the 1950s3. In addition, stationary combustion engines (e.g., power generators & not those for transport or off-road applications) are ubiquitous in our industries and in power generation facilities, which promote the world’s standard of living. Indeed, the demand for available and affordable energy is increasing with the increase in global population and prosperity, particularly in developing countries.

It is important to note that despite all the hype getting generated for alternative fuel engines, there are still no real alternatives that can compete with the ICEs over the entire range of applications that they cover and that, even today, ICEs are undergoing continuous improvement. Combined with the much larger reach & mass acceptance of ICEs make it even more challenging for competing technologies to gain an advantage over ICEs. Focusing on transport, where the energy demand is very large as there are around 1.2 bln light-duty vehicles (LDVs) and around 380 mln heavy-duty vehicles (HDVs) in the world, a number which has been growing by the day. This has led to the daily demand for liquid fuels exceeds 11 bln liters (~3,000 mln tons of oil equivalent per year). All alternatives, whether they are alternatives to ICEs or alternatives to petroleum-based liquid fuels, face very significant barriers to such large energy requirements. But, ill-informed mischaracterisations of combustion have led to a belief in many quarters that the death of the ICEs is both desirable and imminent (some laymen & even experts are trying to spread hashtag #endICEage on social media without even understanding the basics). And for that matter people should understand that just by transition to EVs can never eliminate the ICEs, which have much boarder application range compared to any other prime mover. Also, there is a bigger misconception being spread that most of the world’s GHG emissions come from ICEVs i.e. present day automobiles, a grossly incorrect misconception because they are only a carrier of GHG emissions, each ICEV tend to spread its part of GHG in a larger areas because of it travel reach while for running the EVs the emission is taken care off by the centralsed power plan and combined GHGs are emitted at the power generating station itself..

The Future: Though the EVs are being pushed by whole new eco system of green brigade, ample researches are still being devoted to the development and enhancement of ICEs, exploring different combinations and configurations which will continue to push the technological boundaries of ICEs to enhance their performance. Apart from this, over the course of 150 years of evolution of ICEs and related support systems, robust and interconnected value chains of components have thrived & grown enormously to support the exponential growth of ICEs in variety of diverse applications. Consequently, any future refinements and improvements in ICEs will undoubtedly leverage these established value chains.

Looking ahead, the advancement of Next-Generation ICEs will necessitate global collaborations involving industries, government laboratories, and academia. Several key research areas for this advancement include:

l Performance Improvement Of ICEs: The efficiencies of ICEs exhibit significant variation depending on their type, size & application. For instance, small gas turbines (micro-GTs) typically achieve efficiencies between 15% to 22%, small gas engines operate at efficiencies ranging from 25% to 30%, large modern gas turbines can reach efficiencies of 35% to 40% and a large combined cycle diesel / gas engine achieves a higher efficiency of 35% to 45%. Many global companies are actively engaged in research to enhance the current efficiency of ICEs using innovative approaches such as improved combustion systems, utilising ultra-high fuel injection pressures, deploying novel mechanical layouts of engine components, enhancing engine breathing & heat transfer, improving efficiency of exhaust gas turbochargers, and exhaust gas energy recovery systems with turbo-compounding. Additionally, there is a promising avenue of research involving chemical reforming. Another evolution on the horizon is the development of hybrid ICEs, which hold the potential to achieve thermal efficiencies beyond 50%.

l Engine Simulations: Artificial Intelligence (AI) is currently a buzz word everywhere and hence today’s dynamic automotive landscape in which survival of ICEs is at stake, is also not untouched. AI is playing a vital role in optimising the performance of ICEs by enabling the design of optimal energy utilisation within the engine for improve fuel burning, suggesting alternative space age jacket materials for pushing the limits of ICEs. These advanced simulation models encompass each and every component of ICEs, from larger parts e.g. cylinder head & block to pistons piston rings to smaller parts e.g. gaskets, filters, various nuts & bolts. They efficiently address challenges like lubrication, temperature, friction amongst various moving parts & related lubrication, heat dissipation and its distribution etc. Through these sophisticated simulations tools being used in real time, AI can significantly enhance the overall efficiency of ICEs, leading to improved performance.

l Engine Control: The real-time combustion monitoring with improved burning of fuel as well as monitoring and

managing the cycle-to-cycle operations with innovative calibration and control software, potentially integrating AI-driven onboard physical/statistical model-based control will be improving and enhancing the performance of any future generation of ICEs. Additionally, ongoing analysis focuses on utilising E2X (Engine To Everything) connectivity will also add in improving the overall performance of future ICEVs

l Alternative Fuels For ICEs/ Engine Technologies: Researchers are actively exploring the efficient & multi mix utilisation with multi-fuel combustion in regular ICEs, including that of fossil fuel, natural gas, bio fuel, synthetic fuel4, hydrogen, and NH3. Efforts are also directed towards reducing methane slip5, improving thermal efficiency, and minimising exhaust gas emissions. Furthermore, investigations “e-fuels6” for greenhouse gas mitigation are underway, while “designer fuels7” show promise in enhancing efficiency and achieving near-zero pollutant emissions. These are modified versions of traditional fossil fuel-powered ICEs, utilising Hydrogen, NH3 (Ammonia) or Synthetic Fuel as the combustible fuel. Unlike conventional fossil fuel, these alternative fuels do not contain carbon & Sulphur, resulting in no generation of GHGs. However, there may still be some traces of NOx emissions from these modified ICEs as air contains 74% of Nitrogen. Overall, the use of Hydrogen, NH3 or Synthetic Fuel as ICE fuel offers the potential for significantly reducing GHGs and promoting cleaner and more sustainable transportation.

l Engine Lubrication: Researcher are also working on to reduce energy losses in mechanical friction in rotating parts of ICEs by improving the lubrication systems, particularly for new engines.

l Waste Heat/ Energy Management: Efforts are already underway to enhance the fuel economy of ICEs through thermal management. This on one hand involves reducing heat losses in the engine and on second hand tries to incorporate efficient exhaust heat recovery systems to reuse the wasted heat for after-treatment processes. The future’s key technology lies in the optimal control of these thermal management systems. Solid-state thermoelectric generators8 show promise in converting heat, particularly from exhaust components, directly into electricity. Researchers at Duke University have also proposed using piezoelectric crystals, similar to those that expand with voltage, to actuate direct fuel injectors and generate power through vibration. These innovations hold great potential for further improving the efficiency of ICEs and reducing their environmental impact.

l New Ignition Systems: Ford’s development of new ignition methods, such as the use of near-infrared lasers to ignite the air-fuel mixture at multiple points in a combustion chamber, shows promising potential for enhancing engine performance. Similarly, Maserati’s pre-chamber Twin-Combustion system qualifies as an ignition accelerator, indicating another innovative approach to combustion efficiency. These advancements in ignition technology are expected to lead to significant improvements, including a fuel economy boost of 10~15% and a substantial reduction in NOx emissions. As research and development continue, these technologies could play a crucial role in advancing the efficiency and environmental sustainability of ICEs.

l Variable Compression Ratio: Nissan’s innovative Rube-Goldberg compound connecting-rod mechanism allows for variable engine stroke, which in turn enables the compression ratio to be adjusted infinitely between 8:1 and 14:1. This technology shows great potential, & promises a significant 5% reduction in fuel consumption. By dynamically adapting the compression ratio to match different driving conditions, the ICE can operate more efficiently and deliver improved fuel economy.

l Completely New ICE Concepts: Radically new ICE designs, like the innovative LiquidPiston X-19, face challenges in overcoming industrial inertia. This is an “inside-out Wankel” rotary engine with a uniquely shaped rotor and three combustion chambers within a triangular housing. The LiquidPiston X-1 is actively being developed and has demonstrated impressive power, torque, and efficiency claims. Although the path to widespread adoption may be tough, the automotive industry is intrigued by the potential benefits of such groundbreaking engine designs, which could ultimately lead to more efficient and powerful engines in the future.

l Product Life Cycle Evaluation: Irrespective of the principle or combination of technologies chosen (EV or ICEV), it is critical to thoroughly assess the entire greenhouse gas (GHG) balance and consider the complete value chain. This involves evaluating the environmental impact from the initial production stage, commonly known as “from well to wheel” in the context of fuel, or throughout the entire product lifecycle, referred to as “from cradle to grave”. Taking this comprehensive approach ensures that decisions are made with a full understanding of the environmental implications at every stage. By considering the complete value chain, we can make informed choices that prioritise sustainability and effectively mitigate GHG emissions throughout the entire process.

Way Forward: The ICEs won’t completely lose their charm and will never disappear but rather see reduced usage over time. The technology is likely to persist in some form or another. The charm of internal combustion engines lies in their long and storied history, their widespread use, and the unique characteristics they offer. Here are some aspects that contribute to the charm of IC engines:

l Heritage and History: ICEs have been a fundamental part of the industrial revolution and will always remind us of Ford Model T, an iconic vehicle that helped establish the automotive industry as we see it today. Ford devised new means, a way to mass produce automobiles by creating a massively large backward integrated River Rouge complex on a scale never seen in the industry till then, making automobiles so affordable and accessible that any common man could buy them. ICEs have since then powered vehicles, machines, and industries for over a century, shaping the modern world and facilitating transportation, manufacturing, and agriculture.

l Power and Performance: ICEs are known for their ability to deliver substantial power and performance. Whether it’s the roaring sound of a powerful sports car or the impressive torque of a heavy-duty truck, the mechanical force generated by internal combustion engines was, is & will always remain exhilarating.

l Interesting Mechanical Complexity: ICEs are marvels of engineering. At the average rotational speed of 3000 rpm each revolution last for only 0.02 second in which intricate components (which are more than 200 in numbers) work together to burn fuel to create rotatory mechanical energy. The complexity of their design and operation attracts enthusiasts and engineers who appreciate the beauty of well-crafted machinery.

l Versatility: ICEs can be adapted to various applications, from small engines in lawnmowers to massive engines in ships and power plants. Their adaptability and versatility have made them ubiquitous across different industries.

l Sound, Sensation & Smell: The distinctive sounds, vibrations and smell of ICEs have made people addicted to this machine, who find the sound of a revving engine to be exciting and emotionally evocative.

l Freedom of Mobility: The availability of fueling & service stations for ICEs which have evolved in tandem with each other provided convenience and flexibility of travel, easy refueling, providing a sense of freedom and independence to drivers.

l Immediate (Surge) Power Delivery: Unlike EVs, which has limitation (for high current withdrawal causing overheating) in providing sudden acceleration/power if needed (for which supercapacitors are being used in some of the high performance EVs), ICEs can offer immediate power availability as long as there is fuel in the tank.

l Modifiability and Customisation: Automobile enthusiasts often enjoy modifying and customising internal combustion engines to enhance their performance or achieve specific performance, fostering a strong aftermarket community. EVs have limitations on this front.

l Affordability: ICEs and fossil fuels have been relatively affordable compared to some alternative technologies, making them accessible to a broad range of consumers.

l Safety Awareness: While ICEVs under idle condition do not have many safety issues except when handling the fuel system, in all EVs (BEVs, PHEVs, HEVs), having high-voltage electrical systems (ranging from 100V to 600V), there is always an increased risk of getting exposed to such high voltages while attending these EVs. (Although, their battery packs are encased in sealed shells & tested for stringent use conditions)

Environmental Concern of

ICEVs/ EVs: Despite the above charms of ICEs, it is essential to consider the widespread environmental impact of ICEs, particularly their contribution to greenhouse gas emissions and air pollution. As society moves toward more sustainable and eco-friendly technologies, the appeal of EVs (in the mobility sector) is likely to grow. Nonetheless, the legacy and charm of ICEs will remain a significant part of automotive and industrial history and as such in many of the niche areas, their applications can never be substituted. However, reaching that point will require a significant breakthrough in alternative fuel/ battery technology. Although batteries can currently power heavy vehicles like buses & trucks and their applications for trains are also being explored, the issue of battery disposal at their EOL remains a serious concern.

While the current technologies shift the carbon footprint from one form to another, a breakthrough is needed to truly minimise the environmental impact of all these technologies. Additionally, researchers are investigating various sustainable ways to power prime movers, which means the future may not solely rely on one prime mover, be it ICEs or batteries but could involve entirely different solutions. All it takes is one transformative and practical idea, coupled with cost-effectiveness, to pave the way forward.

However, it must be kept in mind that for humans to survive, energy would be needed which has to come from nature and any utilisation of energy will certainly lead to some or the other kind of environmental degradation – the question for the future is which energy is more environmentally safe & clean and which one could be consumed in a more efficient manner – giving more work/ output per unit of its weight or volume.

Epilogue: The ICEs are few of those wonderful engineering innovation that have evolved, grown, diversified & yet survived over the last 150 years during which they have become better, smoother, reliable, and also affordable, and hence till a worthy alternative appears on the horizon, they are not going to leave the throne as prime movers of the world. Probably, even when an alternative is fond, ICEs will never be entirely vanished but will always be supplemented by newer & emerging technologies incorporating sustainable alternatives. A breakthrough in battery technology or any other innovative energy solution will certainly play a vital role in shaping the future of transportation and energy consumption, however all these new technologies will have to face and overcome a few challenges similar to what ICEs faced in their primitive days such as:

l New Regulations and Policies: this may include factors like electricity tariff of charging EVs and it’s segregation from other uses, open access and captive consumption, additional electricity load, peak demand management, networking and interchangeable service providers & battery swapping regulations.

l Mass Acceptance of Best of the Mobility Technology in Long Run [BEV/HEV or ICEV]: once the current euphoria of EVs stabilises, the range anxiety, limited charging infrastructure, high initial costs, high battery replacement cost, battery technology constraints, and environmental concerns associated with battery production and disposal and also concern about the operational safeties may force people to go back to ICEVs).

l Factors Like Range Anxiety, Safety & Charging Setup, Service, Spares & Energy Transfer, etc.: range anxiety is a significant concern associated with EVs due to the current limitations of the charging infrastructure, and also due to fact that it takes much longer to charge batteries as compared to refueling gas vehicles. Moreover, while EVs must comply with the standard safety norms of traditional ICEVs, they also have to meet extra requirements due to the presence of high voltages & currents within the vehicle for mobility. Depending on the design architecture, these voltages & currents can be substantially higher, introducing specific safety hazards that demand adequate protection. This is a critical requirement related to EVs, as electricity which is invisible and often poorly understood by the general public worldwide.

l Technological Improvements In ICEs: if significant advancements are made in ice technology, with increased fuel, it could be a real challenge to any alternative mobility solutions.

l Consumer Preferences (only for EV Segment): finally, consumer demand pull will play a vital role. If there is still a substantial demand for ICEVs, manufacturers may continue producing them to meet that demand.

l Absence of Henry Ford: last but not the least, EV industry needs someone charismatic like henry ford, a pioneering industrialist who revolutionised the automotive manufacturing/ industry by popularising the use of ICEVs with his iconic model t. His focused pursuit with ICEV with innovative assembly line & concept of interchangeable parts had tilted the whole mobility market in favor of ICEV in a time when the market was ruled by the EVs. (Known as “The Golden Age” of EVs)Undoubtedly, the automotive industry is currently experiencing a period of upheaval, reminiscent of the changes it underwent in the early 20th century. During that time, ICEs emerged victorious, displacing all other existing mobility models such as horses, electricity, and steam, and establishing themselves as the dominant prime mover of the world, more so in the mobility sector. Now, in the 21st century, with advancements in electronics and energy storage systems, a new battle has commenced between EVs and ICEV for supremacy in the mobility sector has begun, however the ICEs have an edge over any other prime mover due to its versatility and even if the EVs my overtake ICEVs in times to come (which may still take many years), ICE can never be eliminate from world’s energy stage because this well-established ICE technology, boasting a remarkable track record of 150 years.

This rivalry is of immense significance for the technical evolution of the mobility sector and has not been witnessed since over the the time, the ICEs’ rose to the pinnacle, routing all its worthy opponents. The outcome of this new “engine war” will heavily depend on various factors that are unfolding with times, focusing on sustainability and global warming fueled by the ever-growing popularity of EVs along with means to harness “Green Energies” in present times.

Author

Prabhat Khare

Executive Vice President, Lithion Power Pvt. Ltd.

BE (Electrical), Gold Medalist, IIT Roorkee

Technology Article Writer, System Auditor, Trainer

Automotive & Engineering Consultant

Auto Sector Expert (Ex Tata Motors,

Ex Honda Cars & Ex Ashok Leyland)

Lead Assessor for ISO 9K, 14K, 45K & 50K (BSI)